Types and Characteristics of Thermal links

Fig. 1 shows the typical construction of thermal cutoff.

The construction is welding fusible alloy to both of lead wire, coating the fusible alloy with resin-based special compound in order to keep its performance for a long period, inserting them to ceramic case, and sealing the both sides by epoxy resin in order to keep its airtightness.

Regarding the operation principle, when the ambient temperature rises and temperature of the thermal element reaches its melting point, the liquefied thermal element is decoupled to both lead wires due to surface tension which is accelerated by the action of surface-coated special compound.

Fusible alloy type thermal cutoff is able to set various functioning temperature in accordance with composition of fusible alloy. But considering accuracy of functioning temperature, long term reliability and so on, the fusible alloy is somewhat limited.

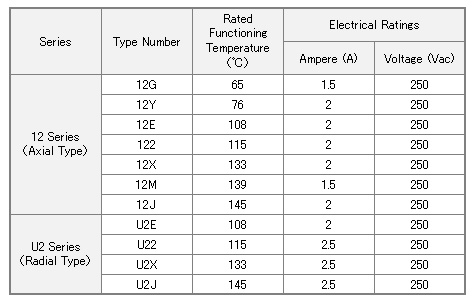

There are several series of products whose rated functioning temperature ranges from 65℃to 150℃in various figures.

Please refer to Chart 1 as an example.

Fig. 1

Construction diagram of thermal cutoff

Chart 1

Alloy type thermal cutoff

Alloy type thermal cutoff

- Easy to choose where to assemble because its construction is simple and small.

- High stability in long term and less characteristics deterioration because the thermal element is alloy.

- High insulation characteristic and no necessity of insulation treatment because it uses ceramic or plastic for its container.

- Superior thermal sensibility and speedy function due to small body.

- Good cost performance

Example Axial Type

Example Radial Type